What is a Shuttle Pallet System?

Shuttle palletsare high-density storage and palletization solutions designed to optimize costs and space utilization. They are also known as radio shuttles or intelligent satellite carts. They operate using a cart that moves along racking aisles to transport goods back and forth. This system autonomously or semi-autonomously transports pallets and can be controlled and monitored remotely by an operator using a shuttle pallet remote control. This works both for routine operations or for rescuing shuttles that have run out of battery or are malfunctioning.

Once an item is placed on the shuttle cart, it is transported to the end of the rack or the next available position. After depositing the pallet, the cart returns to the starting position to pick up the next pallet.

This system has recently gained popularity in the implementation of automated warehouses.

Advantages of Remote Control for Shuttle Pallets Compared to Other Wireless Communications

There are many different wireless communication technologies. Manufacturers in the shuttle pallet sector often consider using alternatives such as Wi-Fi. However, due to the inherent nature of these communication technologies, there can be issues with interference or lack of coverage in certain cases.

Industrial radio frequency, which is the communication method typically used in industrial remote control systems, provides greater range and reliability. This is particularly important in environments where shuttle pallets are used, such as large warehouses with long distances, metal racking structures, and potential obstacles between the operator and the cart’s receiver.

Wi-Fi is often combined with the use of tablets. While these systems allow for the transmission and reception of large amounts of data, they are fully compatible with remote controls for loading and unloading pallets in special cases of maintenance and supervision.

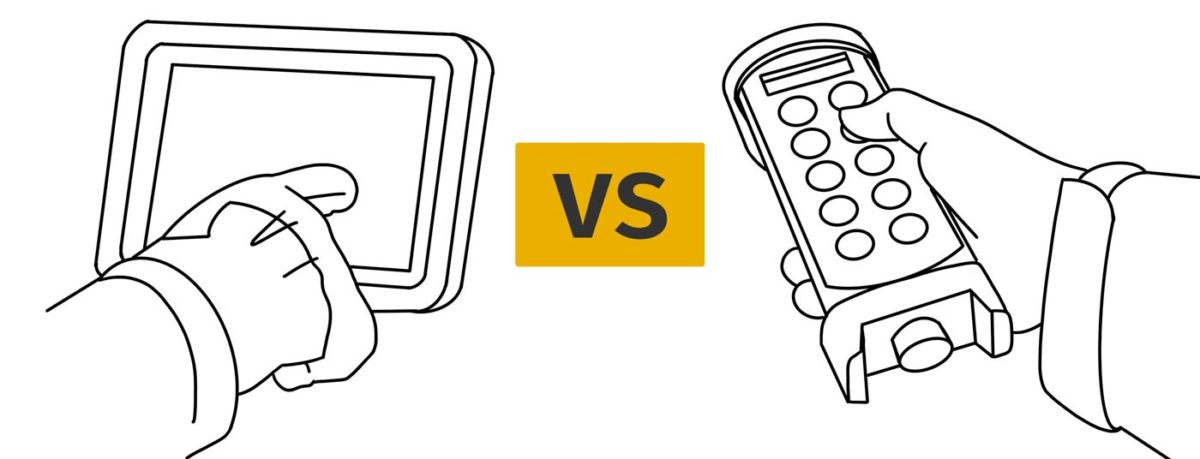

Use of Tablets vs. Remote Control for Pallet Loading and Unloading

Simply put, commercial tablets are not designed for industrial use; they are intended for domestic or office environments. In terms of software, they rely on an app installed on Android or iOS, which requires development and maintenance by external companies.

Tablets can provide a more visual representation of information about the radio shuttle system. However, they lack the durability, sealing, and ergonomic design of an industrial transmitter. Combining both solutions can be an optimal approach, allowing for comprehensive monitoring while maintaining operational efficiency.

Battery life is another crucial factor. Tablets have a touchscreen that can be fragile, do not allow glove use in many cases, and have delicate buttons compared to industrial remote controls. These factors often lead companies to choose remote controls for pallet loading and unloading.

Our transmitters use lithium batteries. Depending on the model, they can provide up to 130 hours of continuous operation (PN-T19-2). This duration is entirely unattainable for any tablet and rarely matched by other remote control systems on the market.

Remote control systems for shuttle pallets are built to withstand shocks, drops, and extreme conditions. They are IP-rated for protection against dust and water and can operate in temperatures ranging from -20°C to +55°C, ensuring reliability in demanding industrial environments.

In an emergency situation, having a certified e-stop button within easy reach provides a significant level of safety for the application.

Remote control systems for shuttle pallets

The front panels can be customized with your company’s corporate colors, logo, and the symbols of your choice for button operations. These panels are made from UV-resistant, scratch-resistant, and liquid-resistant materials and use 3M adhesive for durability.

The TIGER systems feature a stop function with SIL3 PLe certification, while PANTHER is PLd CAT3 certified.

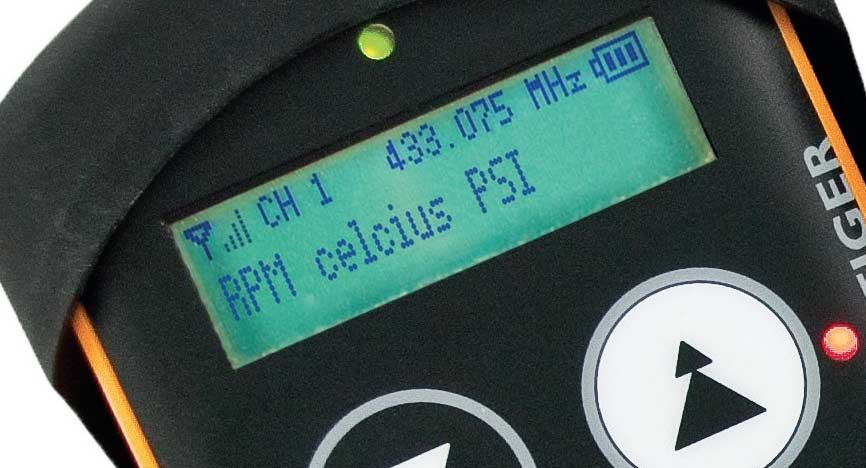

With our TIGER equipment, you can control multiple shuttle pallets from a single wireless transmitter, selecting which one to operate directly from the transmitter itself.

Uninterrupted Operation

We understand that interruptions in a warehouse or logistics center can lead to additional costs. That’s why, in case of a malfunction or loss of the transmitter, replacing it with a new remote control for shuttle pallets is quick and easy:

Each transmitter has a unique code. To replace a transmitter, simply access the menu on the new remote and enter the code of the old one. In just 15 seconds, the first device will be removed from the receiver. Only the new one will be operational moving forward.

Check how it works at this link.

Tiger transmitters can display information from the shuttles, such as alarms, values, pallet data, the currently selected shuttle, and more.

Contacto

Tele Radio supports the world wide preservation of the Tiger with WWF.

Tele Radio supports the world wide preservation of the Tiger with WWF.